Gyratory Sieve Shaker

Price 20000 INR/ Unit

MOQ : 1 Unit

Gyratory Sieve Shaker Specification

- Features

- Easy to Use

- Color

- Blue

- Automation Grade

- Manual

- Material

- MS & SS

- Hardness

- Rigid

- Usage

- Industrial

Gyratory Sieve Shaker Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Gyratory Sieve Shaker

Discover the Gyratory Sieve Shaker, a kingly and redoubtable addition to any industrial setting. Available in a striking blue hue, this outstanding device is engineered with rigid MS & SS materials for superior durability. With manual automation, it offers an easy-to-use design that brings both convenience and cost-effectiveness to your workflow. Enjoy a reduced price, ensuring every deal is efficient and budget-friendly. Manufactured and supplied in India, this shaker is the ideal choice for those seeking reliable performance without excess expenditure.

Comprehensive Application Versatility

The Gyratory Sieve Shaker excels in a range of application methods, making it suitable for laboratories, material testing, and quality control processes. It is widely used in industries such as mining, chemicals, pharmaceuticals, and construction. Beyond standard sieving, its adaptability allows for other applications involving particle separation and grading, making it an invaluable tool across multiple industrial domains.

Efficient Supply and Packaging Solutions

With robust supply ability to cater to the domestic mar, the Gyratory Sieve Shaker is charged from major FOB ports in India, ensuring timely drop-off. Each unit is packaged securely, safeguarding against transit damage and preserving quality. Our commitment to reliable delivery and outstanding packaging ensures customers receive their shaker in prime condition, ready for immediate industrial use.

Comprehensive Application Versatility

The Gyratory Sieve Shaker excels in a range of application methods, making it suitable for laboratories, material testing, and quality control processes. It is widely used in industries such as mining, chemicals, pharmaceuticals, and construction. Beyond standard sieving, its adaptability allows for other applications involving particle separation and grading, making it an invaluable tool across multiple industrial domains.

Efficient Supply and Packaging Solutions

With robust supply ability to cater to the domestic mar, the Gyratory Sieve Shaker is charged from major FOB ports in India, ensuring timely drop-off. Each unit is packaged securely, safeguarding against transit damage and preserving quality. Our commitment to reliable delivery and outstanding packaging ensures customers receive their shaker in prime condition, ready for immediate industrial use.

FAQs of Gyratory Sieve Shaker:

Q: How is the Gyratory Sieve Shaker used in industrial settings?

A: The Gyratory Sieve Shaker is manually operated to facilitate particle separation, grading, and quality control in industries like mining, pharmaceuticals, and construction.Q: What materials are used in the construction of the Gyratory Sieve Shaker?

A: This shaker is made from rigid Mild Steel (MS) and Stainless Steel (SS), providing excellent durability and long-term use in demanding environments.Q: When should one opt for the Gyratory Sieve Shaker over other models?

A: Opt for this model when you need a cost-effective, easy-to-use shaker with outstanding durability and manual operation for versatile applications.Q: Where is the Gyratory Sieve Shaker manufactured and supplied from?

A: The Gyratory Sieve Shaker is manufactured and supplied in India, ensuring reliable domestic availability.Q: What is the process for quality packaging and drop-off?

A: Each shaker is charged from major FOB ports and carefully packaged to prevent transit damage, guaranteeing a secure domestic drop-off.Q: What benefits does the Gyratory Sieve Shaker provide?

A: It offers kingly performance, cost-effectiveness, reduced price, and an outstanding ease-of-use for various industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sand Testing Equipment Category

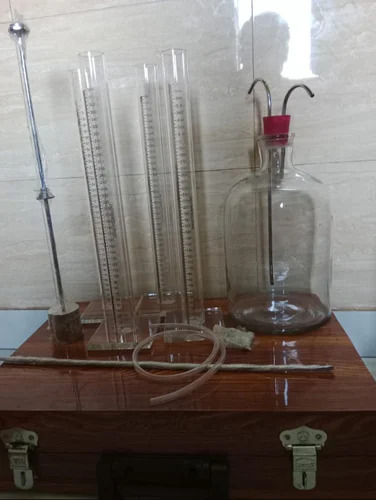

Sand Equivalent Test Kit

Price 11000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Transparent

Features : Easy to install

Automation Grade : Manual

Material : Mild Steel

Flow Cup Viscometer

Price 3500 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver

Features : High quality

Automation Grade : SemiAutomatic

Material : Stainless Steel

Sand Replacement Apparatus

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Blue

Features : Easy to Use

Automation Grade : SemiAutomatic

Material : Stainless Steel

Sand Testing Machine

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver

Features : High quality

Automation Grade : SemiAutomatic

Material : Mild Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry